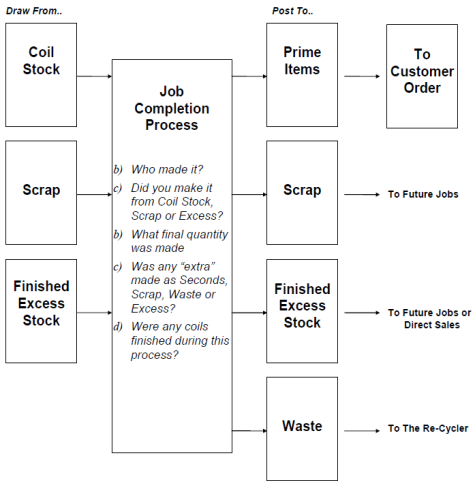

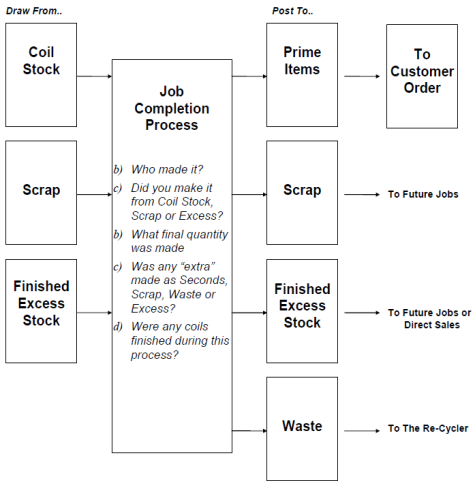

This flowchart shows the flow of raw materials items to manufactured items in MRF, showing that new coil stock, offcuts (scrap) or excess items could all be considered raw material items for the final items assigned to a customer's order. The completion process has been developed to cater for orders that are made from one coil or from many coils of the same colour as shown in the flowchart.

Job Completion Process

To complete the job:

This could be from coil stock, from offcuts or from previously made excess items. If the raw material source was coil stock, enter the coil ID and Micronet updates the coil's yield analysis.

Micronet calculates the amount of offcuts that should have resulted.

The information collected and posted during this process is allocated against the coil yield file to provide feedback on just where your coils have been used and from where your finished items have been made (coils, offcuts or drawn from stock previously made).

The completion process has been developed to cater for orders that are made from one coil or from many coils of the same colour.

The following sections describe how to complete these procedures including: